Manor Tool & Manufacturing Company is a premier metal stamping specializing in punching, bending, forming, and deep drawn stampings. One of our core service offerings is progressive die stamping, a manufacturing process that involves running the workpiece through multiple stations, each of which performs different operations, to achieve the desired component. Equipped with over 60 years of metal stamping experience, highly skilled employees, and a broad selection of manufacturing equipment, we can produce stampings in low quantities for prototyping purposes or high quantities for full production purposes.

Below, we highlight how parts and products are made using the progressive die stamping process.

Overview of the Progressive Die Stamping Process

Progressive die stamping is a metal forming process used to create components for a wide range of industries, from appliances and automobiles to medical devices and plumbing supplies. It is commonly used for high-volume production projects since the progressive dies are built to handle higher speeds.

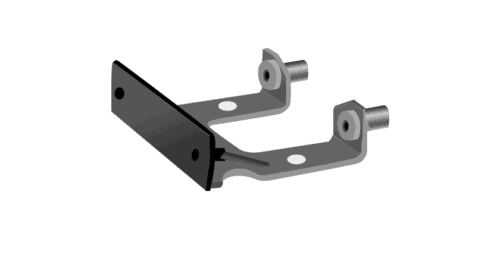

The equipment setup used for the process consists of multiple individual workstations, all of which perform one or more operations on the workpiece. The component is carried from station to station by the stock strip on which it is formed. At the final workstation, the fully formed piece is cut from the strip.

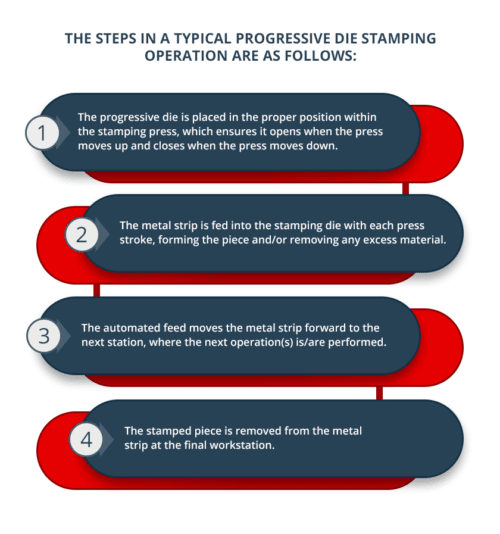

The steps in a typical progressive die stamping operation are as follows:

- The progressive die is placed in the proper position within the stamping press, which ensures it opens when the press moves up and closes when the press moves down.

- The metal strip is fed into the stamping die with each press stroke, forming the piece and/or removing any excess material.

- The automated feed moves the metal strip forward to the next station, where the next operation(s) is/are performed.

- The stamped piece is removed from the metal strip at the final workstation.

Contact Manor Tool for Die Stamping Needs

Looking for a partner for your next progressive die stamping project? Turn to the experts at Manor Tool! Our highly advanced stamping presses with automatic servo material feeders and arbors enable us to work a range of materials up to 35 inches wide, 96 inches long, and 0.005–0.500 thick to tolerances of ±0.0005 inches. Our custom die tooling capabilities allow us to accommodate nearly any component request for one-off or long-term production operations since we can design, maintain, and inventory custom dies for customers.

We are the ideal partner for any stamping project. Our experience and equipment give us everything we need to produce quality parts and products with minimal error rates, which is why our customers come to us time and again for their stamping needs.

Ready to get started on your stamping solution? Contact us or request a quote today. Our representatives are happy to go over your project requirements and restrictions.

Tags: progressive die stamping