Carrie A. Mazzone Kenneth M. Galeno

Controller Vice President

The year was 1979. Manor Tool and Manufacturing was Celebrating its 20th Anniversary.

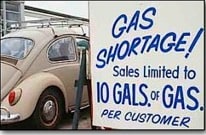

From a run on gasoline in the US in January 1979, to President Jimmy Carter and the Soviet Invasion of Afghanistan in December, it was a “gray time” as the United States faced a yearly inflation rate of 11.2%, and the year-end close on the Dow Jones Industrial Average was 838, while the Fed Reserve interest rates at the yearend was 15.25%. It was a troubling time for employment across the nation.

It was a time when the lines at the gas pumps in Chicagoland stretched for blocks, and as President Jimmy Carter was scheduled to address the nation, the U.S. economy was in question.

“The threat is nearly invisible in ordinary ways. It is a crisis of confidence.

It is a crisis that strikes at the very heart and soul and spirit of our national will.

We can see this crisis in the growing doubt about the meaning of our own lives and in the loss of

a unity of purpose for our nation”. ~ Jimmy Carter, President 1979

The speech was later dubbed the “malaise speech,” despite Carter never using that word.

In 2019, Manor Tool and Manufacturing Celebrated Their 60th Anniversary.

Today, in 2019 the annual inflation rate for the United States is 1.7%; the Dow Jones is trading around the high of 27,000, while the Fed Reserve interest rates are at 5.50%. The U.S. has also become energy independent and once again U.S. manufacturing sector is on the rise.

Ken Galeno V.P. & Carrie Mazzone Controller

Celebrate 40 Years of Service 2019

It was during the malaise climate in 1979, that a young Ken Galeno, who was born and raised in Brooklyn NY, would eventually move away from Brooklyn to attend college in Indiana at St. Joseph’s College in Rensselaer, Indiana. Ken earned his B.A. Degree in Business and Mathematics. After graduation, Ken then relocated to Chicago to take a ground floor position at Manor Tool and Manufacturing in Schiller Park.

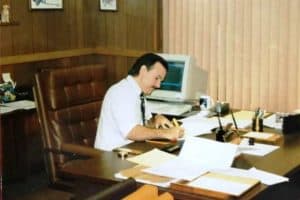

At Manor Tool Ken brought his attention to detail and his business and mathematics skills to the company where he’d begin his career. Ken found himself under the sole direction of the company founder and president, Lee Simeone. Ken initially held a position in the Manor Tool punch press department, which was shortly followed by a “full 5-year apprenticeship program” at the Tooling and Manufacturing Association (TMA) for the Manor Tool In-House Tool Room. The experience as a ground floor trainee then lead Ken into the Manor Tool and Manufacturing Engineering Department for 1 year, followed by the Manor Sales Department. In the year 1991, through his dedication and hard work, Ken was promoted to Vice President of Manor Tool and Manufacturing. Ken has proudly worked to achieve efficiency and effectiveness in every department at Manor Tool and Manufacturing. We thank him for his 40 years of dedication and commitment, and for his sense of customer satisfaction.

Since its inception 60 years ago, Manor Tool continues to be a family-owned company, so it is fitting that the company tagline is “A Family of Precision Component Companies”, which not only include the Manor Tool and Manufacturing headquarters, but also CLL Engineering and Vogel Tool, located in Addison, Illinois. All three facilities were founded on Engineering Excellence.

“Family” has played a big part in the success of Manor Tool over the years, and no other employee’s family has had such a family impact and connection, then our Carrie A. Mazzone, who is also celebrating her 40th anniversary as the Manor Tool and Manufacturing Controller.

Like Ken, Carrie started at Manor Tool in 1979. Upon her graduation from East Leyden High School, Carrie followed the career path of her mother, Ms. Marilyn Hoppe, by joining the Manor Tool Team.

Carrie worked with her mother Marilyn until 2010, when Marilyn retired after 40+ years at Manor Tool. Carrie’s career began in the General Staff Accounting Department at the age of 18 years old. She attended Triton College in the mid 1980’s, and was at Manor Tool for the installation of the “First Green Screen Computer” while also working on the new internal accounting program called “Data Master”. Throughout the years, Carrie immersed herself into the accounting field, and proceeded to attend Harper College to further her education and qualifications. Carrie is proficient in every facet of Microsoft, and all internal company software.

As Manor Tool reflects upon the dedication of these two key employees, Ken and Carrie are the models of principles that have made Manor Tool successful. Ken and Carrie have completed the same training as every successful Manor employee, dating back to 1979. Manor Tool’s apprenticeship program has continued for six decades. Currently, there are five apprentices enrolled in the program at the Manor Tool facility. Though the technology has changed, the program is the same that Ken Galeno went through 30+ years ago to become a Tool and Die maker.

Manor Tool’s dedication to working with the community, local high schools and colleges, are the same today as they were when Carrie was an 18-year old East Leyden Graduate. In 2019, Manor Tool is staffed by local, career-oriented high school and college graduates that have embarked on successful careers from the opportunities that Manor Tool provides, and have remained with the company where the average tenure is 19 years.

Manor Tool continues to work with the former Tooling and Manufacturing Association, known today as the Technology and Manufacturing Association (TMA) .

Deep Drawn Stamping Services from Manor Tool

At Manor Tool & Manufacturing, we offer custom deep drawn stamping services for industries ranging from aerospace and automotive to refrigeration and restaurant service. Our stamping capabilities allow us to produce countless parts and components. To ensure the quality of our products, all deep drawn stamped products, assemblies, and sub-assemblies are subjected to rigorous ISO-certified quality control measures throughout the production process.

If you need a deep drawn stamped product, our expert team can take your project from design to end product. For more information on our stamping capabilities or to partner with us, contact us or request a quote today.