Metal Stamping Trends for 2021

Leave a CommentIt looks to be an exciting year ahead for the metal stamping industry. The market grew steadily in 2020, and it’s expected to see continued increases through 2026 as demand for precise metal stamped products increases. Through the challenges that this year presented, Manor Tool has been proud to serve the manufacturing and fabrication needs of a diverse group of clients. We look forward to continuing these relationships in 2021.

The Impact of COVID-19 on Metal Stamping

The pandemic left its mark on all aspects of manufacturing, encompassing supply chain disruptions, massive demand changes, and operational changes to support social distancing and other safety measures. It’s been a year of uncertainty, and all businesses have been forced to take one day at a time and pivot to meet the ever-changing circumstances.

The industry was already facing challenges from unstable international trade relations when pandemic-related shutdowns started changing demand. With less construction and air travel, for example, there has been less need for certain metal components. As businesses deemed “non-essential” temporarily shut their doors, manufacturers lost many of their customers. Conversely, manufacturers of essential goods found themselves overwhelmed with orders for personal protective equipment, medical and testing equipment, and more.

As companies adapted to meet these challenges, they’ve hit fast-forward on the adoption of certain technologies and innovations that are likely here to stay. The metal stamping forecast includes two big changes:

- Manufacturers will rely more heavily on data to guide strategic planning

- With remote access capabilities for machinery, the location of many skilled workers will matter less moving forward

The technology for these advancements has been around for a while, but the upfront costs of comprehensive software and hardware changes have previously been difficult to justify. In light of COVID-19, many manufacturers will be adopting new technologies sooner rather than later.

What to Look for in 2021

What to Look for in 2021

Metal stamping trends in 2021 will be driven largely by low material costs and an ever-growing need for the type of intricate, lightweight parts that make airplanes and automobiles more fuel efficient without sacrificing safety. Increasing competition in the industry will fuel innovation, even in these challenging times.

The metal stamping forecast is promising. For aerospace and defense metal stamping alone, growth (according to Meticulous Market Research, Ltd.) has been projected at a CAGR of 4.6% through 2027, ultimately reaching $33.6 billion by the end of that period. Although COVID-19 has heavily impacted the aerospace industry, this sector has been on an upswing in recent years that will continue as we move beyond the pandemic. Many older aircraft are being replaced by planes featuring the latest fuel-efficient, sound-reducing technology. Clips, connectors, and fasteners for assembly and signal, communications, and power systems are expected to drive the greatest demand for metal stampers.

Steel also hopes to make a comeback by 2021, perhaps with lower prices. Though steel prices are currently rising after taking a hit over the summer, they’re expected to reach their peak and decrease moving into 2021.

To take the temperature of the industry, the Steel Market Update (SMU) polls steel buyers on a regular basis to see how they’re feeling about the market. SMU’s Future Sentiment poll has shown that steel buyers remain optimistic about the future of the steel sector.

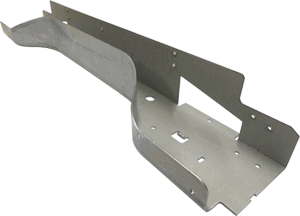

Metal Stamping Services From Manor Tool

At Manor Tool, we’re excited about the metal stamping forecast and how we can contribute to the industry in 2021 and beyond. With six decades of experience, we offer the highest quality deep-drawn stamping, punching, bending, forming, and more. We’re dedicated to staying on top of metal stamping trends to deliver the products our clients need and want.

Feel free to download our e-books to learn more about metal stamping. Please contact us or request a quote to see how we can help with your project.

What to Look for in 2021

What to Look for in 2021