Applications and Tips for Transferring Tooling

Leave a CommentDeveloping effective transfer tooling procedures lets small and medium-sized manufacturers minimize their tool development costs and hedge against unpredictable component suppliers. Tooling is an expensive process, but it typically involves only a one-time cost, so anything that can make the tooling process more affordable will greatly impact your overall expense portfolio. As the trade war between the U.S. and China continues to heat up, it’s now more important than ever to consider transferring tooling back to American manufacturers to mitigate increased costs and other supply chain disruptions as a result of tariffs.

External suppliers perform a number of time-intensive processes during tooling development so that you don’t have to. Third-party tooling services include:

- Machining

- Heat treating

- Routing

- Barcoding

- Turning assembly

- Pressing

- Debugging

- CMM final inspection

When you let other manufacturers perform these tasks, you can dedicate more time and resources to applications more central to your company’s mission.

In this post, we describe eight transfer tooling strategies that will enable you to get the most from outsourcing your tooling production.

Eight Steps to Successfully Transfer Your Tooling

1.) Make Sure Everything’s Covered in Your Contract

All parties subject to the transfer tooling agreement must sign nondisclosure agreements to ensure that any new innovations remain between those concerned. NDAs must cover part prints, quality assurance policies, and production requirements. Additionally, governmental and third-party regulators often require legally sound contractual agreements to be signed before work can begin.

2.) Create a Strong Partnership that Emphasizes Communication

A partnership based on trust and open communication between the businesses will ensure that parts arrive on time and that nothing is lost in translation. Both companies must be willing to take the appropriate steps to ensure that communication channels remain open throughout the process.

3) Perform On-Site Assessments Early and Often

It’s important to have a solid understanding of your transfer partner’s capabilities before entering an agreement. Additionally, once production has begun, frequent and respectful on-site assessments will ensure that you have as much information as possible on the status of your tooling.

4) Agree on a Clear Production Schedule

Create a detailed transfer schedule using data from on-site assessments. The schedule must include transfer dates for all parts and tools while allowing enough time to produce the tools to your standards.

5) Build Enough Safety Stock to Allow Efficient Tooling Transfer

The supplier must provide enough safety stock that you can use during the validation of production equipment and processes at the new facility. Typically, business partners set up a six-week timeframe within the transfer schedule, although it’s important to allow for the possibility of additional shifts and/or weekend work to make sure everything’s running on time.

6) Ensure You Buy the Correct Consigned Equipment

The third party may need to buy nonconsigned equipment to successfully build your transfer parts. Consignment equipment typically includes tooling and spares, fixtures, inspection gauges, and all other product-specific equipment.

7) Validate All Transfer Tools Before Ending Your Contract

When the third-party’s transfer tools leave production, you should ensure that they’re all compatible with your existing facility. Many companies validate transfer tooling by analyzing their new parts’ similarity to existing parts and performing golden sample processes.

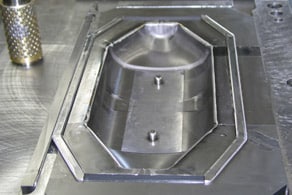

8) Design Production Molding For Use in the Next Transfer

Once the tools have been validated and incorporated into your production processes, make sure you or your contractor save the production mold to simplify the transfer tooling process next time you go through it.

Applications for Transfer Tooling

Just about any industrial manufacturer needs to develop effective transfer tooling procedures. A wide range of manufacturers regularly contract third parties to ensure that their next generation of tools is of as high quality as possible. Industries that implement comprehensive transfer tooling procedures include:

- Sheet metal stampers

- OEMs

- Appliance manufacturers

- Automotive and aerospace OEMs

- Furniture assemblers

- Machine tool shops

- Medical device manufacturers

Transfer tooling can work with a wide range of metal products, such as:

- Aluminum

- Cold-rolled steel

- Spring steel

- Stainless steel

- HSLA

Manor Tool: A Trusted Source for Transfer Tooling

Manor Tool & Manufacturing is an ISO 9001:2015–certified company that can help you with all your transfer tooling requirements. If you’re looking for more best practices on how to implement the most effective transfer tooling procedures, download our free eBook, “Everything You Need to Know About Transferring Tooling.”

If you’re looking to embark on a transfer tooling procedure of your own, feel free to contact us at your earliest convenience to request a free quote.

Manor Tool Teams Up With University of Illinois Engineering Students to Improve Space Utilization

Leave a CommentThe manufacturing industry is facing an oncoming crisis. If current trends continue, there will soon be a lack of engineers with the skills needed to meet the demands of a growing economy. Manor Tool is committed to working towards finding solutions that help close this engineering skills gap. As part of our ongoing efforts, we recently joined forces with the University of Illinois (UI) at Urbana-Champaign.

We partnered with UI students in the Senior Engineering Project program, which is a graduation requirement for engineering majors. The program presents scenarios that students are likely to run into during their careers. By collaborating with industry leaders like Manor Tool and Manufacturing, students gain essential knowledge that prepares them for what lies ahead in their professional work.

Learning in a Real World Classroom

Once a week, the student team members have a conference call with their contacts at their partnered business. They discuss the issues they’ve been working on and any developments that have come up. It’s an excellent opportunity for the students to apply the concepts they’ve been studying in actual applications. This prepares them to start their careers, while also teaching them concepts that will benefit the companies they work for.

Manor Tool Gets Involved

In 2019, we were paired with a team from UI that included students Anthony Alvizu, Nicola Dama, and Zechen Sun. The goal of the project we tackled was to improve space utilization, so we could balance production with customer requirements. We were looking for ways to make production more efficient, which would help us respond to the demands of a large project. The team analyzed the facility and how space was used, then presented ideas to expedite production.

The Manor Tool team was glad to have the experience of working with the students from UI. We value the opportunity to support and guide the next generation of engineers, as well as share the expertise and industry knowledge we’ve gained through the years.

An Enriching Experience for Engineering Students and Manor Tool

Manor Tool has grown throughout the years to become a superior quality metal stamping company. Our skilled and experienced staff will work with you from design through completion, regardless of the size of your project. We use state-of-the-art technology and processes to achieve the efficiency and precision you need.

For more information about what we do or to learn about past projects, check out our resource library.

Supplier of the Month Nomination

Leave a CommentAt Manor Tool, we abide by a value proposition—a commitment to the high-quality service, execution, and delivery expected and deserved by our customers. A high standard of excellence and commitment to the value proposition sets our company apart and attracts long-term customers and partnerships.

This dedication to service has earned Manor Tool a nomination for the Gallis Award. This award is given every month to suppliers and individuals who go above and beyond expectations by a subsidiary of Menasha Corporation, a $2 billion corrugated and plastic packaging manufacturer. In February 2019, the incredible team at Manor Tool was nominated as Supplier of the Month.

Manor Tool’s Nomination

Gallis Award Nomination presented to Ms. Lucy Lopez Q.A. Manager and John Creighton Sales Manager

When Menasha’s subsidiary launched a new seedbox, Manor Tool did everything we could to support a successful release. Our team made beneficial changes to the production schedule and worked overtime to meet stringent project requirements. Throughout the process, we held weekly meetings and kept in close communication with the Seedbox team to make sure production stayed on schedule and deliveries were completed correctly and on time.

Nominating us for the Supplier of the Month Gallis Award recognizes the superior level of service we provided. We strive to create an exceptional experience for the customer, and we are proud to receive this acknowledgement of our ongoing commitment to excellence.

Manor Tool’s Capabilities

Manor Tool boasts a long history of excellence in service. Founded in 1959, the company has evolved and expanded its offerings to serve a variety of industries and applications. We provide a wide range of services, including:

- Design and engineering

- Tool and die fabrication

- Metal stamping

- Deep-draw stamping

- Custom tooling

- Finishing services

With our end-to-end services, we never need to outsource any part of a project. We understand that keeping the work in-house improves delivery times, ensures the highest quality, and saves money for the end customer. We are ISO 9001:2015 certified and just last year installed a new 330-ton Komatsu Press.

We continuously look for new ways to improve our ability to serve our customers. For example, the Manor Tool team has been working on logistics to further improve shipment and delivery times. We work diligently not only to improve the services we provide, but also on improving our partnerships. Relationships are important to us, and when we work to serve a relationship rather than simply to create a finished product, the high-quality work reflects that commitment.

This subsidiary of Menasha has relationships with more than 3,000 vendors, and only four of them were nominated in February. Manor Tool is proud to be named among them, an honor that recognizes Manor Tool as a valued vendor.

We look forward to meeting and exceeding the expectations of old customers and new customers alike. If you’re looking for a manufacturing partner, we invite you to download our eBook: Choosing the Right Partner for a Successful Metal Stamping Project. This resource outlines what you should consider when choosing a vendor, including company history, capabilities, and strengths and weaknesses.

If you have any questions or would like to learn more about how we can serve your project needs, please contact us.