3 Key Characteristics of a Successful Metal Stamping Partnership

Leave a CommentAn important decision for any business to make is choosing the right partners. When it comes to the metal stamping industry and its many applications, factors such as company history, scope of capabilities, and a focus on innovation are vital elements to consider in any potential partner.

Here are a few essential characteristics to look for when deciding on the right partner for your next metal stamping project.

Company History

The company you choose for your metal stamping partner should possess a strong portfolio and established history of working with challenging yet successfully completed projects. It’s also important for the values of a potential partner to be aligned with yours, providing transparency in their processes and methods of operation.

Scope of Capabilities

While a potential partner should have expertise in the techniques of metal stamping, they should also offer value added services that extend beyond their core practices. For example, Manor Tool began strictly as a tool and die shop, but now we also specialize in forming, bending, punching, and deep-drawn metal stampings. We provide a wide range of capabilities, which means we never outsource projects to a third party. This increases efficiency and saves costs in the long run.

Focus on Innovation

The manufacturing industry is rapidly changing, and a strong partner will be ready and prepared for whatever the future brings. Modern equipment and processes such as automation can greatly increase efficiency and reduce long term production costs. With a metal stamping partner that employs the latest manufacturing techniques, you’ll continue to receive high quality components that can help you to stay ahead of the competition.

Manor Tool: History, Scope, & Focus

Manor Tool and Manufacturing has a long and proven history of delivering successful, quality metal stamped parts, a broad scope of services, and a deep commitment to staying at the forefront of innovations in the manufacturing industry.

Our full range of services includes metal stamping, deep drawn stamping, progressive die stamping, custom tooling and fabrication, machining, manufacturing design and engineering, and finite element analysis.

To learn more about the qualities of an ideal business partner, download our eBook, “Choosing the Right Partner for a Successful Metal Stamping Project” today.

Manor Tool: 60 Years in Metal Stamping Excellence

Leave a CommentAfter being honorably discharged from the Marine Corps in 1945, Lee Simeone, like so many other young men, found work in America’s booming industrial sector. At the time, the United States was undergoing exponential economic growth as it operated under the Marshall Plan to rebuild Europe. Simeone found work making tools and dies, rising through the ranks of local plants in the Chicago area until, in 1959, he decided to found his own company.

Thus, the Manor Tool & Manufacturing Company was born. Simeone made a $9,000 down payment on a facility in Schiller Park, IL, from which our company grew into the expansive metal stamping, fabricating, and part assembly powerhouse it is today.

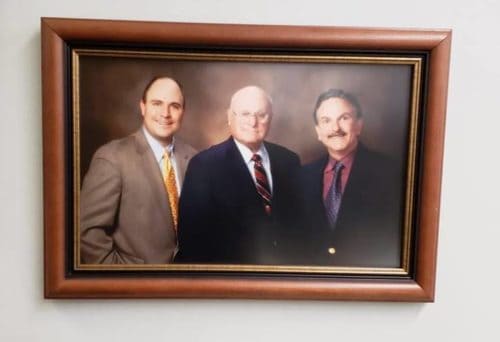

After leading the company for 36 years, Lee Simeone went into semiretirement in 1995. He promoted his son, Thomas Simeone, and son-in-law, Ken Galeno, to take on the mantles of president and vice president, respectively. Under the leadership of Simeone and Galeno, Manor Tool has grown to a 32-press facility, offering a full range of services including:

- Design and engineering

- Tool and die fabrication

- Metal stamping

- Deep-draw stamping

- Custom tooling and fabrication

- Secondary machining and finishing services

Company History and Accomplishments

For this reason, we’ve spent the last number of years investing in our employees, putting future technology, equipment, and leadership directly into the hands of the people who have helped us come so far. We’ve also spent the last 11 years expanding our footprint across Illinois, acquiring Vogel Tool in 2008 and creating CLL Engineering in 2011 to produce tube fabricating tools and gasket dies, respectively.

Manor Tool also seeks to cement its place as a community resource to both the manufacturing world and to our neighbors in Illinois. Many of our employees count themselves as members of the Technology and Manufacturing Association, which is one of the largest associations of its type with accomplishments dating back to 1925. We also partner with local high schools and community colleges to sponsor shop classes and other training programs for the next generation of manufacturers.

Preparing For the Next 60 Years of Success

If you would like to learn about our offerings at any of our divisions, contact us and request a free quote today.