Metal Stamping FAQs

On this page, you will find answers to some of the most frequently asked questions that the Manor Tool team receives.

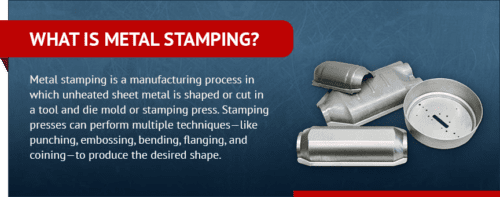

What is metal stamping?

What is the deep draw metal stamping process?

Deep draw stamping produces hollow metal components by pulling and stretching the metal through a die that contains a cavity. The depth of deep-drawn parts is typically determined by the number of times the metal is drawn.

What is progressive die stamping?

In progressive die stamping, a series of stamping dies cuts, punches, bends, or performs some other operation on a single workpiece until the finished part exits the final station.

What are the types of metal fabrication techniques?

Metal fabrication techniques can create specific shapes from metal sheets, bars, or rods. In addition to metal stamping, deep draw stamping, and progressive die stamping, other fabrication techniques include:

- Extrusion: A piece of metal, usually a bar, is forced through a narrow die, producing a round tube cross-section.

- Forging: Metal is shaped by striking it with force, typically in a die or with a hammer.

- Machining: Machining is an umbrella term for subtractive metalworking techniques such as cutting, drilling, carving, and other shaping operations that involve removing excess material to produce the required component.

- Milling: A type of machining technique, milling is frequently performed by CNC equipment, allowing precise, multiple-axis cutting as the tools move around the part.

- Turning: As another type of machining, turning involves rotating parts on a lathe while a stationary blade cuts away unwanted stock material. CNC machinery commonly performs turning operations, producing very precise and repeatable results.

- Punching: Punches strike metal to indent or perforate it according to specific designs.

- Welding: Welding connects separate metal parts together through the application of heat and/or pressure.

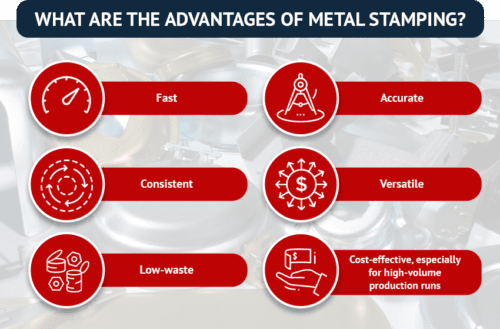

What are the advantages of metal stamping?

How do I determine the best materials to use when metal stamping products?

The specific characteristics of a material and its ability to be stamped or machined successfully will greatly influence material selection. Cost and aesthetics may also influence ideal material choice. Make sure the material you choose fits the function and performance specifications of your application.

For example, manufacturing metal baskets for office use likely does not require high-performance steel or even stainless steel. On the other hand, manufacturing counters for industrial kitchens does require high-quality, food-grade stainless steel.

The most common types of metal stamping materials include:

- Ferrous metals: steel, stainless steel, carbon steel

- Nonferrous metals: aluminum, brass, bronze, zinc

- Custom alloys: beryllium copper, beryllium nickel

- Precious metals: gold, silver, platinum

When die stamping metal components, how do you choose the right process?

The best metal stamping process achieves the desired results while requiring the fewest steps, producing the least scrap material, and being the most cost-effective. For example, reusing existing dies or utilizing progressive stamping for large production runs save time and money in the long run. Manor Tool’s design and engineering team partners with customers to produce accurate, quality parts as efficiently as possible.

What is the production volume of Manor Tool’s presses?

At Manor Tool, our 30-press facility can handle a thousand to over a million parts with ease. We use our own tooling services or your existing dies to produce results exactly to your specifications.

What differentiates Manor Tool from other metal stamping companies?

With specialties that include deep drawing, punching, forming, and bending, Manor Tool can accommodate low to high volume productions using a combination of turrets, press brakes, and hard tooling. If you partner with us, you will experience the benefits of our:

- ISO 9001:2015 certification

- Full-service metal stamping capabilities

- In-house design and tooling expertise

- Medium- to high-volume capacity

- Decades of experience serving a broad spectrum of industries

Choose Metal Stamping & Fabrication Services at Manor Tool

At Manor Tool, we offer cost-effective, custom stamping, tooling, and fabrication solutions with superior design and quality assurance. We produce accurate and consistently stamped parts from a variety of metals and plastics. Whether you need prototyping or a million-part production run, our team has the skills and equipment to exceed your expectations.