Metal Stamping Services • Custom Sheet Metal Parts

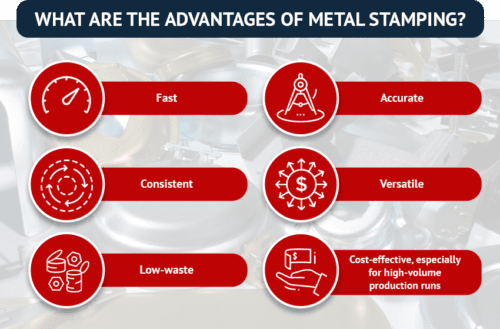

Utilizing sheet metal and one or more stamping dies, the metal stamping process shapes and cuts a metal workpiece to generate components in an array of designs. A highly accurate and repeatable manufacturing technique, metal stamping can quickly and efficiently produce high product volumes without sacrificing quality, all at a low per-part rate.

Manor Tool & Manufacturing Company provides a broad range of metal stamping services to clients in industries ranging from electronics and consumer goods to construction and automotive aftermarket components. Whether you’re interested in a prototype or small production run, or you have a high-volume project, our team has the resources and expertise to get the job done right. As a custom manufacturer, we offer turnkey, end-to-end services from design consultations and tool making through coating and assembly to ensure your precision products meet your unique project requirements.

High-Quality Custom Metal Stamping Solutions From Manor Tool

To create custom metal stampings, Manor Tool leverages our 65 years of experience, expert staff, and well-equipped facility to provide solutions tailored to your needs. Our comprehensive metal stamping capabilities allow us to:

- Work with a wide range of material options. Stainless and carbon steel, aluminum, and brass are just a few of the metals our team works with to meet diverse customer needs.

>> Learn More About The Materials Commonly Used for Metal Stamping & Fabrication - Accept small as well as large projects. Manor Tool has the capacity to handle prototyping, high-volume orders, and everything in between.

- Create precision parts with intricate shapes. Metal stamping can achieve tight tolerances, even on parts with complex geometries, for optimal accuracy and part performance.

- Provide advanced forming processes. Our team is highly experienced in progressive die stamping, deep drawing, piercing, forming, coining, and more to deliver quality solutions for your unique project.

- Offer secondary service options. To offer turnkey solutions for our customers, we also provide heat treating, welding, deburring, plating, and other secondary and finishing services.

Our Metal Stamping Specifications

Custom Stamped Metal Parts for Industrial Applications

A variety of industries use metal stamping to create parts and components. Some of these industries include:

Aerospace

Aerospace applications require highly specialized parts with consistent repeatability and quality. The precision offered by metal stamping makes it an ideal solution for producing a wide range of aerospace components, such as the following:

- Brackets

- Fasteners

- Flexible couplings

- Subcomponents

- Torsion springs

Original Equipment Manufacturers (OEM)

OEMs tend to produce machinery and parts in high volumes. Metal stamping provides a fast, cost-effective method for high-volume production.

Oil & Gas

The oil and gas sector uses durable parts for connectors, seals, and a range of other applications. Metal stamping offers the precision and quality necessary to support safe operation in this demanding industry. Common metal stamped components that Manor Tool creates for the oil and gas sector include:

- Fuel injectors and pressure regulators

- Rotary valves

- Universal joints (U-joints)

- Valve actuator parts and valve seals (subcomponents and shut-off handles)

Medical

There is no room for error in medical devices and other medical applications. As such, the medical sector relies on metal stamping parts to produce consistent, high-quality components and tools. Our healthcare offerings include the following:

- Biopsy trays

- Dental office table, chair, and light components

- Instrumentation connector parts

- Medical gas fittings and scissors

- Surgical forceps and retractors

- Thermometers (thermostat bezels)

Fluid Power

Fluid power applications require a range of high-quality washers, flanges, and other parts that can withstand the pressure ranges and corrosiveness of the application’s environment. Metal stamping offers an ideal solution for fabricating these essential components. Common parts for the fluid power industry that we create with metal stamping are:

- Hydraulic fittings, hose fittings, and valves

- Mounting flanges

- Quick connectors

- Rotary joints

Construction

Metal stamping is a cost-effective, reliable choice for construction component manufacturing. The process is capable of creating precise bends and shapes with the capacity for high-volume production. The metal stamping technique is also compatible with several strong, durable, and malleable metals that are well-suited to manufacturing construction tool parts. At Manor Tool, we can create components for:

- Fasteners and staplers

- Hand, power, and pneumatic tools

- Nail guns

Types of Metal Stamping

As a stamping parts manufacturer, Manor Tool specializes in two methods of metal stamping: progressive die stamping and deep drawn stamping.

-

Progressive Die Stamping

Progressive die stamping utilizes multiple workstations, each performing a different action to incrementally create a metal component. This fast, cost-efficient process moves the metal part from station to station on its stock strip, enabling great control over the positioning of a part for optimal quality control. We use progressive die stamping presses ranging in capacity from 22 to 400 tons to achieve tight tolerances of ±0.0005 inches.

-

Deep Drawn Stamping

Deep drawn stamping is highly precise. The stamping press draws a metal sheet radially into the die cavity, shaping the material into a hollow three-dimensional form — often cylindrical — without resulting in any joints or seams. Offering repeatable accuracy, the deep drawn process also results in stronger metals because of the strain hardening that occurs during production. Our stamping presses can achieve large as well as very deep stamped components using this process.

Your Trusted Partner in Metal Stamping: The Manor Tool Advantage

Manor Tool is committed to quality, accuracy, and consistency in every stamping project. As a full-service, ISO 9001:2015-certified operation, we offer in-house design, tooling, and custom metal stamping and fabrication solutions to ensure quality at every stage. With decades of experience serving key industries with metal and plastic stamped goods, we know how to cost-effectively produce everything from prototypes to high-volume runs of complex components.

Ready to Get Started? Contact Manor Tool for Your Metal Stamping Needs

At Manor Tool, it’s our goal to solve our customers’ production challenges through high-quality metal stamping at competitive prices. Contact us today to learn more about our abilities, or request a quote for your next metal stamping project.