Our Services

In 1959, we opened our doors at Manor Tool & Manufacturing Company as a tool and die shop. We have since grown to become a top-tier metal stamping company with our core specialties including progressive and deep-drawn stamping services. From low-volume orders and prototypes to high-volume orders with advanced tooling requirements, we can do it all. We want to ensure that our customers receive the exact part they need at the highest level of quality.

Metal Stamping & Deep Draw Stamping Services

This frame section is composed of pre-coated cold rolled steel. Before stamping this component, we perform a finite element analysis to maximize process efficiency.

Custom Tooling & Fabricating Services

This bracket is manufactured by using several processes, such as progressive die stamping, tapping, plating and screw insertion.

Secondary & Machining Services

This commercial quality cold rolled steel boom is stamped on a press than can create compound angular forms.

Manufacturing Design & Engineering Services

Using aluminum killed, draw quality, cold rolled steel, this terminal box was developed using hard tooling provided by our customer.

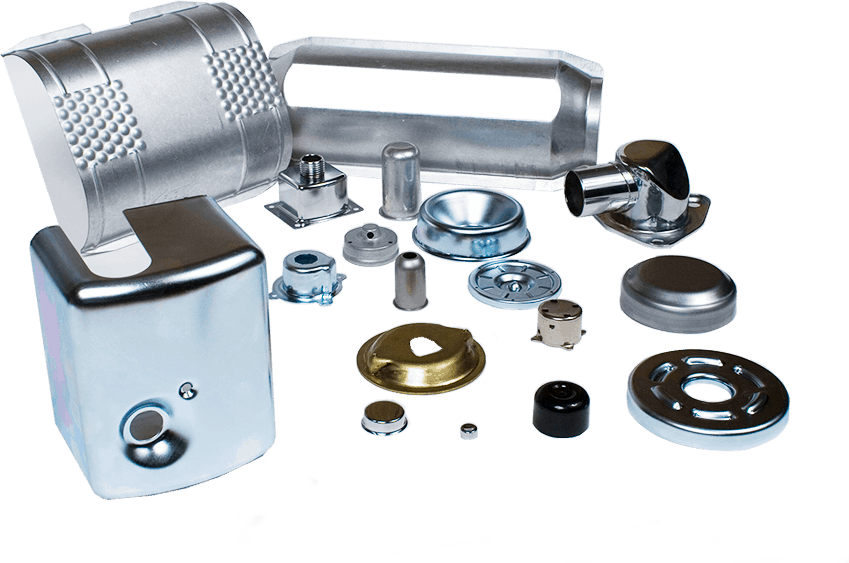

Metal Stamping Services

For six decades, Manor Tool & Manufacturing Company has built a reputation as one of the leading providers of professional and reliable metal stamping services, specializing in punching, bending, forming, and deep drawn stamping of metal parts and components for numerous sectors.

Metal Stamping

Metal stamping provides our clients with a cost-effective way to produce high-volume product runs. Metal stamping dies are used to cut extremely precise shapes into a metal workpiece. The process can involve one or many dies progressively in the same machine. Setup for metal stamping is simple and quick, reducing lead times and allowing us to offer rapid turnaround times. Some of the industries that incorporate metal stamped components include:

- Aerospace

- Construction Tools

- Electronics

- Military & Defense

- Oil & Gas

- Medical

Each industry has its own specific requirements, which is why we offer an array of metal stamping capabilities to fulfill their requirements. Examples include:

Deep Drawn Stamping

A process that turns metal sheets into axisymmetric components. Most of the components that come out of this process are cylindrical in design, but box-shaped designs are also possible.

Progressive Die Stamping

This method passes the workpiece through a series of dies that progressively perform different operations on the material to form the final part.

Metal Fabrication

Metal fabrication encompasses a vast range of processes used to form or shape metal components. We can perform metal fabrication on a range of materials including aluminum, copper, nickel, carbon steel, and brass.

We frequently perform metal fabrication services for a large array of industries, including:

- Aerospace

- Construction

- Energy

- Automotive

Our metal fabrication capabilities include forging, extrusion, drilling, drawing, welding, milling, turning, and punching.

Custom Tooling And Fabrication

We offer custom tooling and die services for our customers to accommodate their unique production needs. Using an array of advanced equipment and software, our experienced engineers can expertly develop custom tooling for single and multi-station stamping assemblies.

Our engineering team offers the following services:

- Design consultations – Our engineers will review your design and identify areas of improvement and offer suggestions for refinement.

- Cost-reduction analysis – Our engineers will provide you with alternate design options to help you save money. They will also ensure that the design will work with current manufacturing methods.

- Prototype development – We will create a prototype quickly to allow customers to review it and make changes before beginning a full production run.

We use Finite Element Analysis software to run through projections of the final results of various metal stamping applications. This allows us to identify and design flaws early and give our customers realistic expectations of their final product

Secondary Machining

We offer a wide range of secondary machining and finishing services, including:

- Brazing

- Deburring

- Fabrication

- Packaging

- Painting

- Plating

- Powder-coating

- And many more

If your order requires the special attention of one of these services, just let us know and we can help. We also offer welding services that include:

- MIG welding

- TIG welding

- Spot welding

- Projection welding

Quality Assurance

Our in-house quality assurance team monitors quality at every level of production — from design to distribution. Our expert tooling engineers work very closely with quality engineers to make sure every product we produce meets our high standards. This includes work done with machines such as:

- Brown & Sharp Digit-Hite Plus

- Tesa Micro-Hite

- Sherr-Tumico Fully Programmable CNC 2 Axis Optical Comparator

Contact us today to learn more about our services and how we can help boost your production capabilities, or request a quote to get started.