Custom Tooling & Fabricating Services

As a full-service one-stop-shop, Manor Tool & Manufacturing Company designs and builds custom tooling in-house. Our engineers develop tooling for our precision metal stamping services using our AutoCAD & Unigraphics software for tooling design operations and our MASTERCAM software for CNC machining and wire EDM operations.

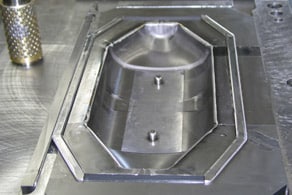

Custom Metal Stamping Dies for Stamping Services

Our tooling equipment and capabilities allow us to build single and multi-station progressive dies ranging from 48 to 96 inches with a 400-ton press capacity. In addition to designing and building new tooling, we can run and repair existing tooling.

A stamping die is a precision tool used in press equipment to cut and form sheet metal into a particular shape or profile. It contains cutting and forming sections that are typically made from tool steel—a special hardenable steel—or wear-resistant materials, such as carbide or other hard metals. Depending on the part and process specifications, the die or dies employed vary significantly in size and design.

Equipped with over 60 years of stamping experience, the team at Manor Tool and Manufacturing Company has the knowledge and skills to design and create custom dies for a variety of purposes, including for the following:

Cutting

Cutting is one of the most common processes performed with a stamping die. The machine operator feeds the sheet metal between the two sections of the die through a small gap referred to as the cutting clearance. The application of force to the die by the press equipment decreases the cutting clearance, ultimately stressing the metal to the point of failure and producing a cut edge with a portion referred to as the fracture zone (i.e., or break line) and a shiny portion called the cut band (i.e., shear).

Some of the most common cutting operations for which stamping dies are used include:

- Blanking

- Lancing

- Notching

- Piercing

- Shearing

- Trimming

Coining

Coining is a stamping operation that flattens or breaks the burr on the edges of a stamped metal part. This process smoothens the edge of the coined area of the part and adds strength to specific sections of the finished piece, eliminating the need for secondary operations such as deburring and grinding.

In-Die Tapping

In-die tapping is one of the most complex and complicated operations performed with stamping dies. The process offers the opportunity for significant cost-savings but requires experience and skill that only a few designers and toolmakers have acquired.

Forming

Forming dies work by applying compression, tension, or both to sheet metal in processes such as bending, drawing, flanging, and stretching. The success of the operation is dependent on the metal used. It must demonstrate mechanical characteristics that are strong enough to serve the part’s intended function and able to bend and stretch within the specified limits.

Quality Tooling From Manor Tool & Manufacturing

Manor is an ISO 9001:2015 certified company dedicated to ensuring quality in every project. Equipped with more than six decades of expertise in custom tooling for metal stampings and formed components, we will work with you to develop a plan that fits your exact needs. With fully customizable services, comprehensive engineering reviews for existing and new parts, and a range of secondary services, we are fully committed to a partnership with each of our customers.

To learn more about our custom tooling services, view our videos for an overview of our metal stamping die maintenance process, as well as our metal stamping, die design, and machining processes. If you are interested in learning more about our custom tooling and fabricating services, contact us today.

Tooling Specifications

| Industry Focus: |

|

|---|---|

| Metal Stamping Dies: |

|

| Tool Manufacturing Capabilities: |

|

| Tooling Die Features Available: |

|

| Intended Application: |

|

| Tolerance (+/-): |

|

| Tooling Die Length: |

|

| Tooling Die Width: |

|

| Maximum Part Weight/Maximum Lifting Capacity: |

|

| Materials (Metals): |

|

| Fixturing |

|

| Equipment Capabilities |

|

| Equipment |

|

| Stocking Programs |

|

| Production Volume |

|

| Lead Times Available |

|

| Industry Standards |

|

| File Formats |

|